WITHOUT A HOLLOW SPINDLE LATHE

YOU

ONLY HAVE "HALF"

A DRIVESHAFT SHOP!

You're a Professional, don't

settle for anything less!

us or

call us at 800-645-8652

us or

call us at 800-645-8652

specifications

|

Speed |

0-400 RPM |

|

Spindle Bore |

10" (250mm) |

|

Chuck Type |

3 Jaw |

|

Horsepower |

7.5 HP |

|

Power Requirements |

208-230 Volt 3 Phase |

|

Dimensions |

57"H X 35"D X 67"L |

|

Shipping Weight |

4,000 lb. |

|

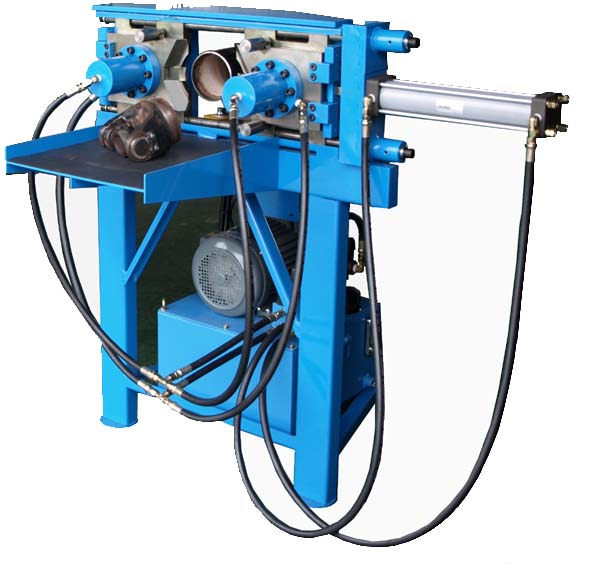

THE RENOWNED DIAL SHAFTCUTTER MODEL 2012-G DRIVESHAFT LATHE |

TO BUILD A DRIVESHAFT YOU SOMETIMES

HAVE TO PERFORM TIME CONSUMING TASKS, LIKE CUTTING OUT WELDS,

CUTTING TUBING, SQUARING THE ENDS OF THE TUBING AND DRESSING

THOSE ENDS FOR WELDING PROIOR TO PRESSING IN THE NEW YOKES

OR STUBS. TIME IS MONEY AND SAVING TIME IS MAKING MONEY. THERE

IS NO BETTER "TIME SAVER" IN YOUR SHOP THAN A DIAL SHAFT CUTTER.

TAKE A LOOK AT THE VIDEO.

|

|

SPECIFICATIONS |

|

Speed |

0-400 RPM |

|

Spindle Bore |

10" (250mm) |

|

Chuck Type |

3 Jaw |

|

Horsepower |

7.5 HP |

Power

Requirments |

208-230 Volt 3 Phase |

|

Dimensions |

57"H X 35"D X 87"L |

|

Shipping Weight |

4,000 lb |

|

|

|

|

|

|

|

|

|

DIAL MODEL 2040-G HOLLOW SPINDLE COMBINATION

LATHE |

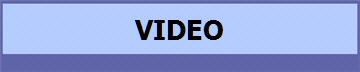

This is a Dial Lathe. It's

an American Designed and engineered turning center. It's our

number one best seller because it's

versatility is unsurpassed in the driveline shop. It's a multi

speed unit with a super 250mm (10") large bore spindle. In

addition, it's A solid one piece 40" gap bed, equipped with

a center support and

a MT-4 tailstock. This all adds up to its rugged versatility.

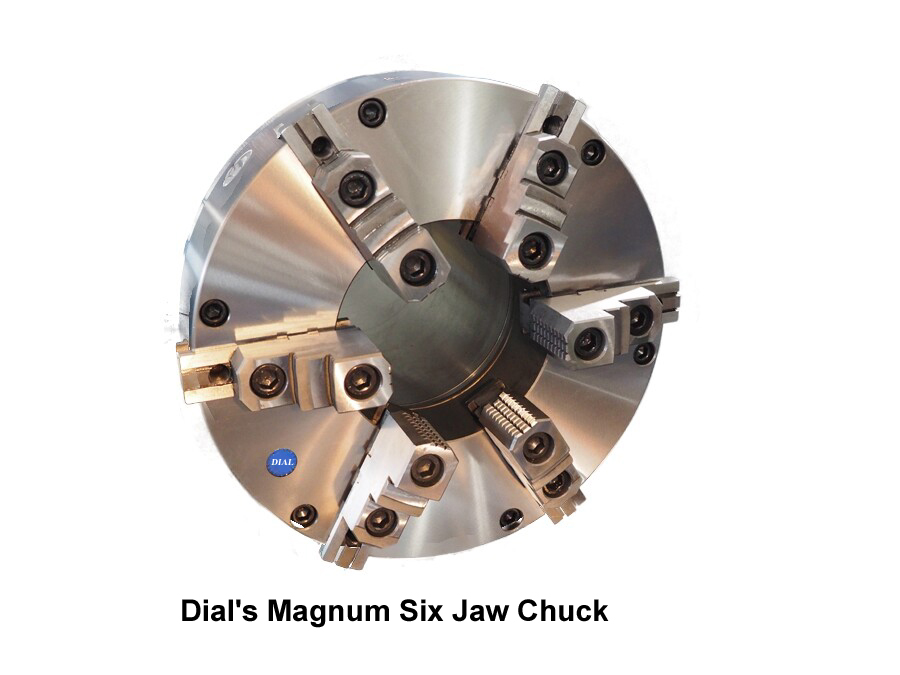

There is more…To handle those large "RPL" and "SPL" weld yokes,

we have equipped this lathe with a Dial three jaw self centering

chuck that will easily pass those RPL's and SPL's. You may also,

by special order, equip the lathe with our new Dial "Six Jaw"

self centering chuck. This is especially useful when clamping

down on an aluminum or carbon fiber shaft, and it has a 9" plus

through Hole. Want a 60" bed? We

can fix you up with that as well.

You can

get all of this and at a price that will make you smile. Click

on the video and see how efficiently it will add to your bottom

line.

|

|

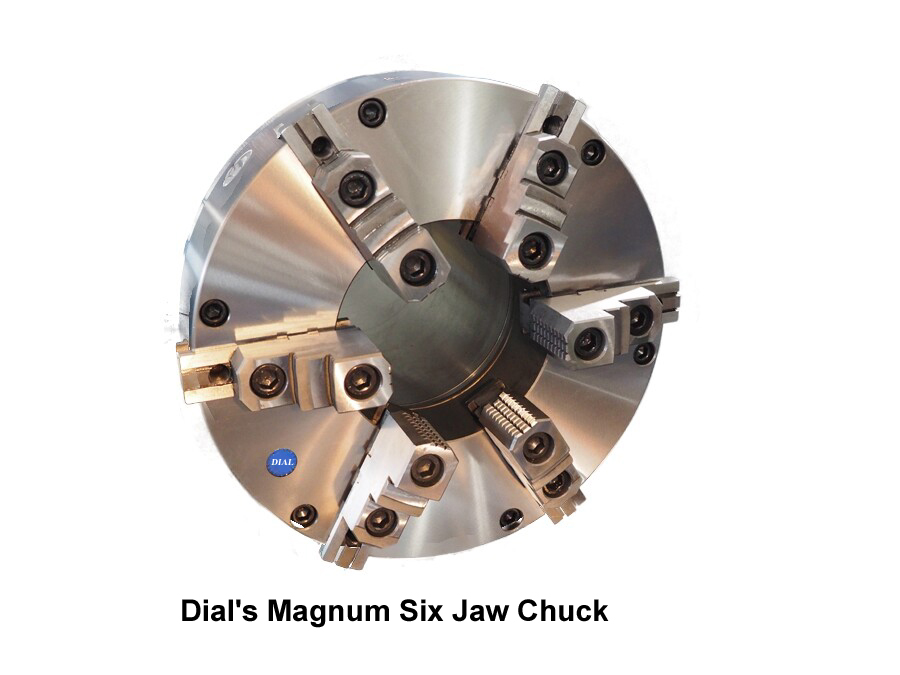

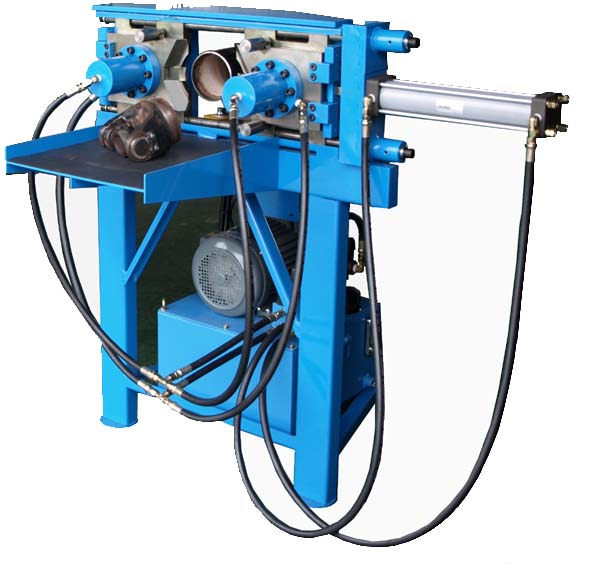

Dial Model YP-4

Yoke and

Stub Puller |

This wonderufl addition to the driveshaft shop is proving to

be one of the greatest time savers to come along in years. Ask

any experienced "tech" and they will tell you it's not always

enough to machine out the weld. Remember, the yokes and stubs

were pressed in prior to welding with a 10 or 15 ton press. That

process now has to be reversed either with a "young bull with a

big hammer," or with a dedicated machine.

|

|

Click on the Video |

|

|

Cold Saw Model

DCS-350 |

|

When time and space are at a premium,

the DCS-350 cold saw can be a real asset to a busy shop.

An example would be when you are modifying a driveshaft and need

to just shorten it. The Answer…Use the cold saw to quickly remove the

necessary material from the shaft, keeping in mind that the ends

will STILL need to be chamfered for a good weld. A twisted tube comes

in and you want to salvage the yokes and stubs, then cut off

just the ends with the cold saw, chuck the ends up in a lathe,

cut out the weld and remove the yoke or stub and then

re-tube.

You will find that this valued addition

to your shop will be used for a myraid of other tasks.

Call for a

brochure and specifications. |

| |

|